Superfinishing machines

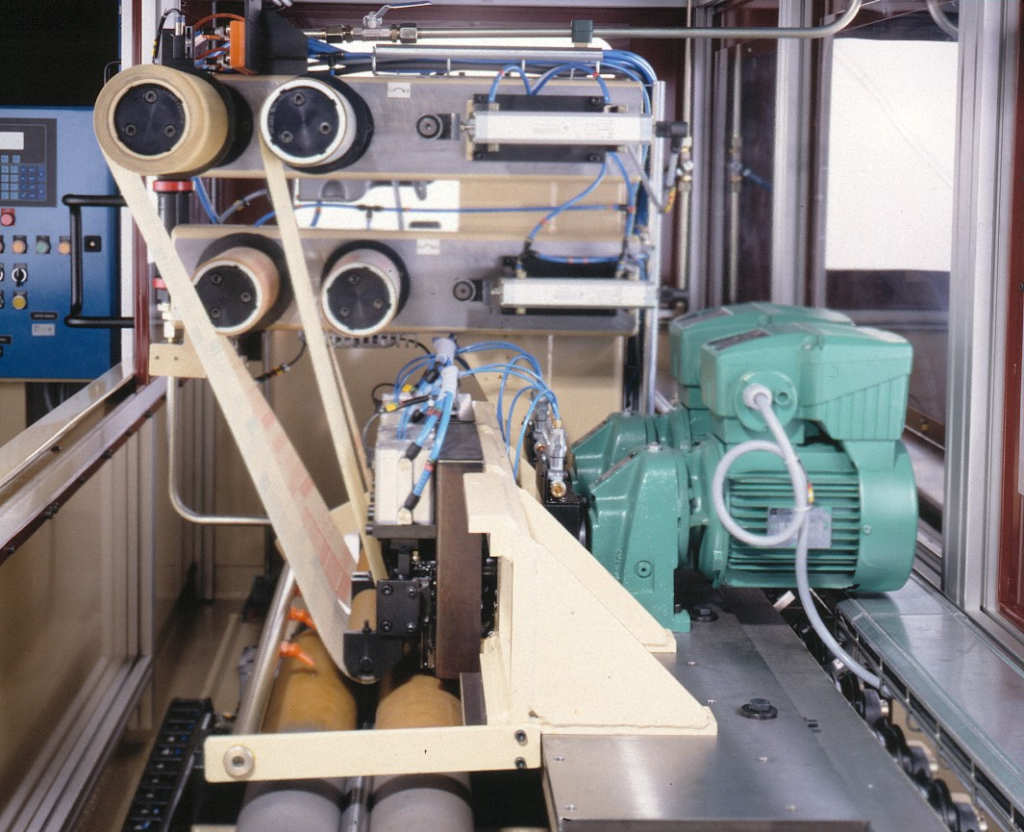

New generation flexible superfinishing machines for all types of shafts (gearboxes, electric motors, etc.) for rolling bearings and seal spans.

- SPMS Supramatic special machines type CMA

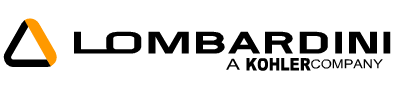

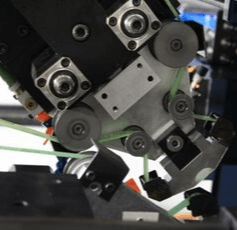

- The SPMS type CMA superfinishing machine uses standard microfinisher heads.

- These units consist of a roll of micro-abrasive strips, mounted on the device.

- The film runs smoothly and continuously along a polyurethane contact roller.

- The film runs smoothly and continuously along a polyurethane contact roller.

- Continuous abrasive replacement ensures a consistent finish ovtable oscillation (sideways beating) of the pressurising head improves the surface finish and considerably reduces the The adjustable oscillation of the pressure head improves the surface finish and considerably reduces the polishing time.

- TMUA through SPMS processes, provides finishing solutions for all types of powertrain, transmission, steering and automotive suspension components.

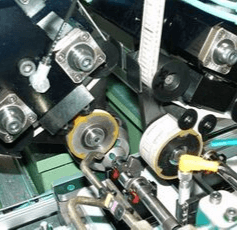

CMA Superfinishing Machine for Gearbox Shaft

Features

Length – Up to 100/300/600mm

Weight – Up to 10 kg

Production 6

60-120 parts per hour

Built to automotive standards

Requirements according to powertrain specifications

Application :

- Surface improvement

- Improved geometry

- Bearing diameters

- Oil seal diameters

- Cylindricity, circularity, straightness

- Abrasive belt and micro-abrasive stone

Caractéristiques :

- Fully automated

- PLC/HMI control system

- Modular design

- Automation features

- Automation features

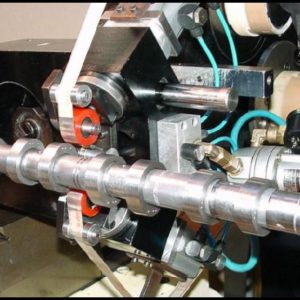

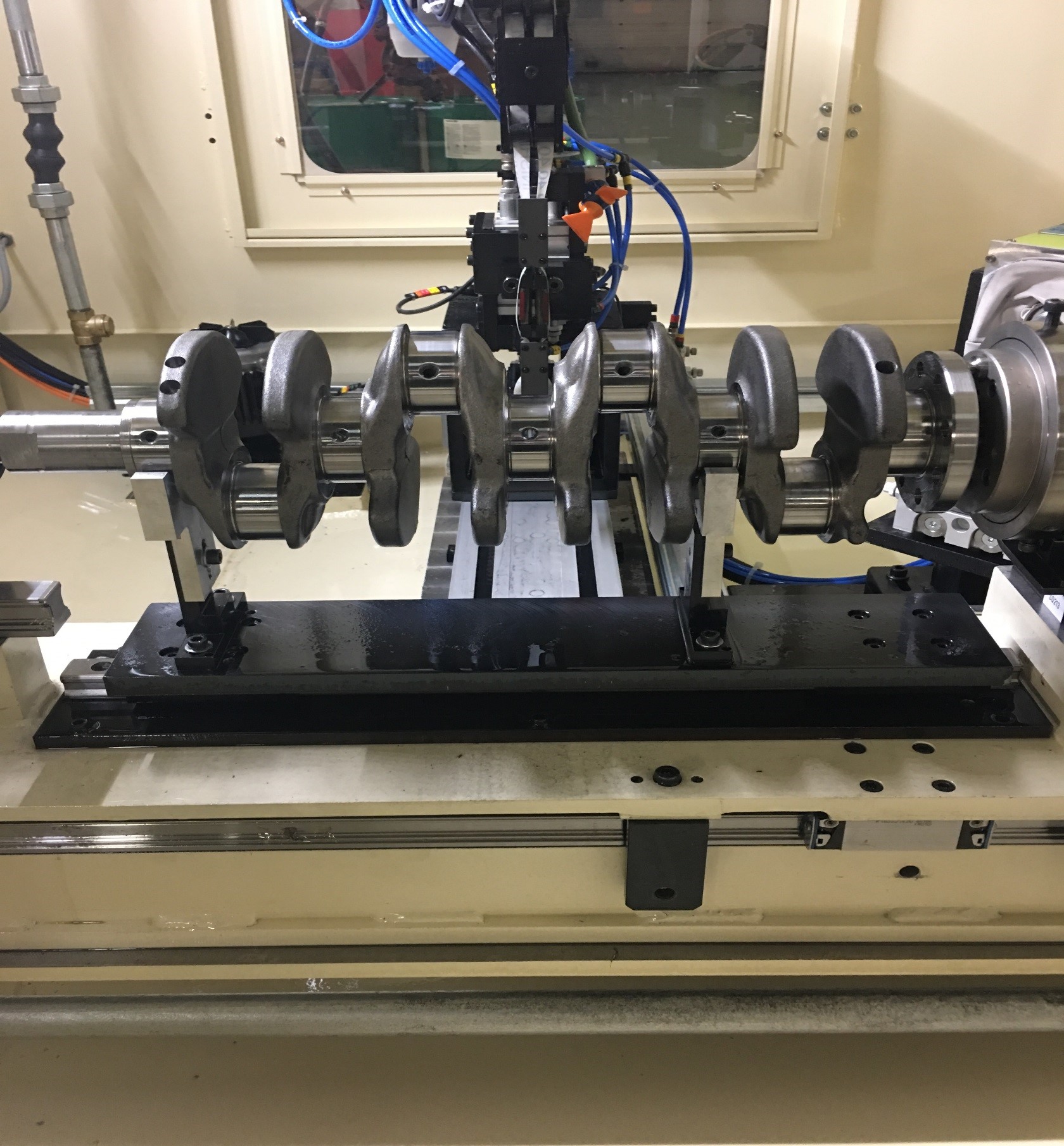

Superfinishing machines for crankshafts and camshafts

Superfinishing machines for camshafts

Superfinishing machines for camshafts

Single and multi-station design machines with automatic conveyorized workpiece transfer or manual loading equipped with SPMS patented CMA type superfinishing heads with oscillating and indexing abrasive belts. Plunge or indexing type tooling for cams and bearings with optional integrated brush deburring system (see deburring machines tab)

Superfinishing machines for crankshafts and camshafts

Superfinishing machines for camshafts

Single and multi-station design machines with automatic conveyorized workpiece transfer or manual loading equipped with SPMS patented CMA type superfinishing heads with oscillating and indexing abrasive belts. Plunge or indexing type tooling for cams and bearings with optional integrated brush deburring system (see deburring machines tab)

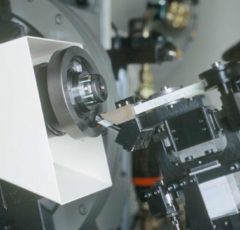

Internal superfinishing machine for synchro gears and cones.

Features

- SYNCHRO AND SPROCKET MACHINE

- Diameter – Up to 100 mm

- Weight – Up to 2 kg

- Typically 60-120 parts per hour

- Built for the global car industry

- Powertrain specifications

Application

- Surface improvement

- Internal bore sizes

- Conical surface diameters

- Micro-abrasive tape

Features

- User-friendly and fully automatic

- PLC /HMI control system

- Modular design

- Automation features

- Patented process

Superfinishing machine face bearing crankshaft

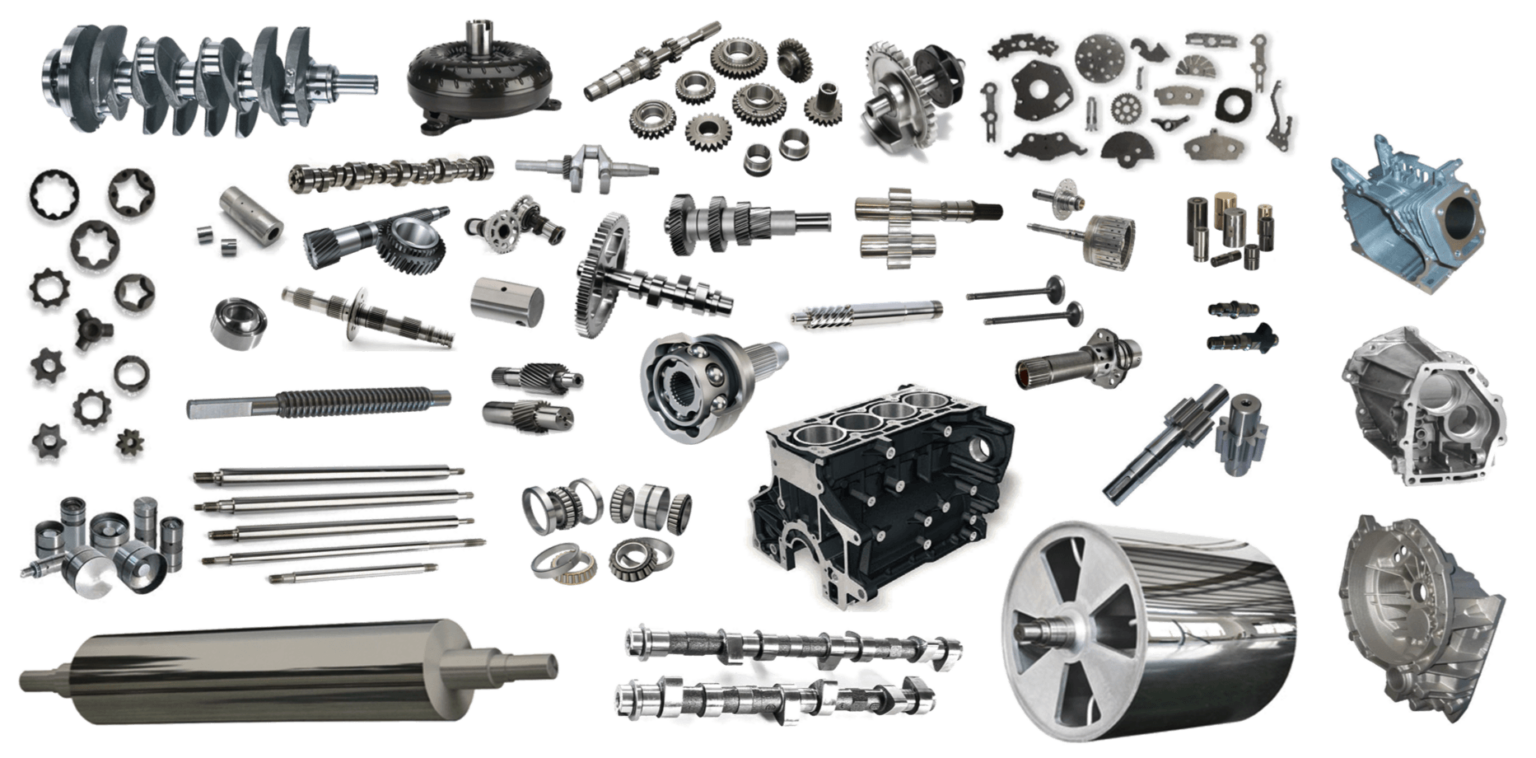

Example of parts

Are you looking for a company to manufacture your abrasive machine?

We have full control over all stages of production, think about TMUA.

2 voies des Mineurs,

ZA Chambaret Sud – 43300 Langeac

SPMS’s main customers