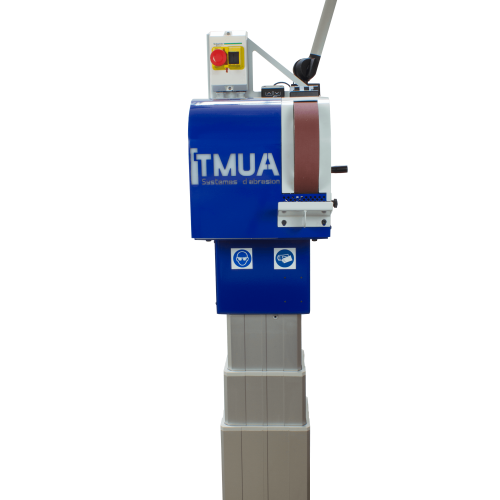

WR

Using 1 or 2 identical or different high-powered working units, the WR can be used for deburring, trimming, brushing, superfinishing or manual polishing of workpieces of any material and shape.

The amount of material to be removed determines the power of the machine, the WR series with 3 available powers allows you to adapt your machine to the work required.

The motor and unit assembly can optionally be mounted on a reinforced sheet metal base.

The working units can be rotated around the motor shaft, the housings are equipped with Ø 120mm suction nozzles.

Motor specifications :

WR30 : 2.2 Kw – 3000rpm* – Power supply 220/380v three phase

WR40 : 3 Kw – 3000rpm* -Power supply 220/380v three phase

WR50 : 4Kw – 3000rpm* -Power supply 220/380v three phase

(*option 1500rpm)

Control box :

Basic version: Thermal-magnetic circuit breaker and emergency stop.

Variable speed drive version: Variable speed drive in box with potentiometer, emergency stop and mushroom button.

4 units are available on the right or left

Tank Unit

Equipped with a 350X175mm plate with workpiece support shelf, protective cover and Ø120 suction nozzle for 1500 X 150 abrasive belts. These elements make the tank unit perfect for face dressing. Special tank protection screen as an option.

Backstand Unit

Backstand with contact wheel Ø250X50 (or Ø250 X 75mm or Ø250 X 100mm in option) smooth or grooved (as required) with protective cover and Ø120mm suction nozzle. For sanding belts 2500X50mm (or 2500 X 75 or 100mm depending on the chosen wheel width). Practical for deburring on the wheel. Optional protective screen.

Brush Unit

Unit for one wire brush Ø 250mm maximum. Supplied with housing and protective screen with Ø 120mm suction nozzle

Polishing Unit

Designed for finish polishing (with polishing compound), this unit allows the mounting of bonded abrasive wheels or ventilated cotton wheels up to 400mm Ø. Optional housing and protective screen.

Accessories

- Reinforced sheet metal base

- Reinforced sheet metal base

- Frequency inverter

- Protective screen adaptable to all units

- LED Lamp

- Choice of colours

DECLARATION OF CONFORMITY FOR NEW EQUIPMENT SUBJECT TO SELF-ASSESSMENT WITH INTERNAL MANUFACTURING CONTROL

Machine conforms to the European regulations in force today

Machine conforms to the European directive

The Machinery Directive 2006/42/EC

The EMC directive 2014/30/EU

The Low Voltage Directive 2014/35/EU

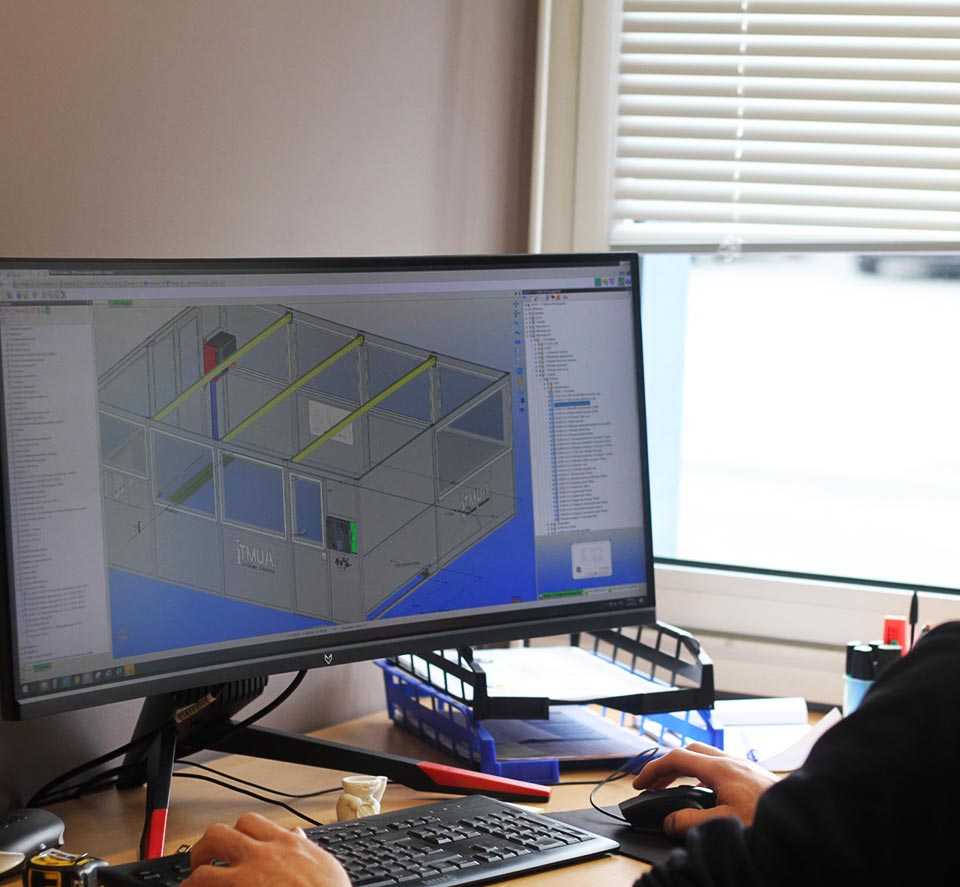

Are you looking for a company to manufacture your abrasive machine?

We have full control over all stages of production, think about TMUA.

Any request is possible, do not hesitate to contact us.

2 voies des Mineurs,

ZA Chambaret Sud – 43300 Langeac